No products

Bloc lien

Raw-stuff

- Raw-stuff

- Compressors

- Equipment

- Gearboxes

- LSTC profile

- Электродвигатели

- Шнековые конвейеры

- Весоизмерительное оборудование

Viewed products

-

Polypropylene fiber

Produced by Belgian technology and on...

New products

-

Комплекс АТОМ-ПРО-200 ОТ, 380В

354 000 ₽ -

Комплекс АТОМ-ПРО-200 ОТ, 380В

341 000 ₽ -

Комплекс АТОМ-ПРО-200 ОТ, 380В

265 000 ₽ -

Комплекс АТОМ-ПРО-200 ОТ, 380В

321 650 ₽ -

-

Gerotor pump NGV-2500B (hopper), for mortars

Gerotor pump NGV-2500B with a receiving hopper for various types of...

470 250 ₽ -

-

Фасовочная станция ССМ-ФС-3

1 950 000 ₽ -

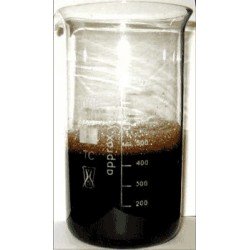

Polypropylene fiber

New product

Produced by Belgian technology and on the Belgian line (Belgium Fibers Ltd). Features of polypropylene fiber application (building microreinforcing fiber) in cellular concrete (non-autoclave cured aerated concrete). Fibre foam concrete is foam concrete reinforced with fiber (L fiber = 6-12mm).

19950 Items

In Stock

More info

Fibrofoam concrete is currently an inexpensive and versatile building material. It is used for block and monolithic construction of buildings and structures.

A significant disadvantage of cellular concrete is poor bending performance, as in any porous material, the bending load is taken by thin interstitial partitions. The use of polypropylene fiber is a method of eliminating this drawback.

The effectiveness of applying fiber (building fiber reinforcement) with a minimum-optimal dosage of 500 gr./m3 (0.1% of the brand, D600 - 0.6 kg) in foam concrete is as follows:

- When you break the forms of ribs not splinter, there is no destruction of the block, ie, the quality of the product increases, the number of defects is reduced significantly.

- The increase in bending strength practically nullifies the number of rejects during transportation.

- Introduction of fiber contributes to reduction of setting time and accelerates mold turnover.

Fiber is a material in the form of polypropylene fibers, used for disperse reinforcement of foam concrete, polysterene concrete, concrete structures. This increases the resistance to tensile, abrasion, shock loads.

Foam concrete, polysterene concrete and concrete containing polypropylene fiber has a serious impact resistance and resistance to splitting compared to conventional concrete. Tests show a 5-fold increase. The increased impact resistance and splintering resistance with polypropylene fiber is the result of absorbing large amounts of energy when the fibers are stretched after cracking in the cement mortar.

Polypropylene fiber can be used in heavy industry, military applications to increase explosion resistance, and in areas of high seismic activity.

Fiber Applications

- concrete floors and screeds

- additives for dry mixes

- Paving slabs and curbs

- concrete admixtures

- printed concrete

- coastal reinforcements

- Reinforcing cementation additives

- concrete and mortar additives

- petrochemical industry

- reservoirs

- precast concrete

- shotcrete

- reinforcing additives

- plaster

- repair compositions

- dry mixes

- fiber concrete production

- piles

- airfield slabs

- foam concrete, etc.

- as well as eliminates the need for steel reinforcement mesh