No products

Catalog

Bloc lien

Equipment for foam concrete

-

Комплекс АТОМ-ПРО-200 ОТ, 380В

265 000 ₽ 283 000 ₽

New products

-

Комплекс АТОМ-ПРО-200 ОТ, 380В

354 000 ₽ -

Комплекс АТОМ-ПРО-200 ОТ, 380В

341 000 ₽ -

Комплекс АТОМ-ПРО-200 ОТ, 380В

265 000 ₽ -

Комплекс АТОМ-ПРО-200 ОТ, 380В

321 650 ₽ -

-

Gerotor pump NGV-2500B (hopper), for mortars

Gerotor pump NGV-2500B with a receiving hopper for various types of...

470 250 ₽ -

-

Фасовочная станция ССМ-ФС-3

1 950 000 ₽ -

Equipment for foam concrete There are 33 products.

-

Mini-plant SSM-200-12MK, equipment for...

Mini-plant SSM-200-12MK - installation for the production of monolithic foam concrete (CLC) and foam blocks (CLC block). The standard equipment of the plant is supplemented with a Remeza SB4 / S-100 compressor with a capacity of 360 l / min, 10 atm.

317 200 ₽Под заказ, производство 2-4 недели -

SSM-200-12M mini-factory, for the...

The SSM-200-mini-plant has on its board a mixer, a new generation of foam generator and a pump for supplying foam concentrate. Application of the mini-plant: for monolithic pouring with foam concrete or the manufacture of foam blocks of various densities (from 150-1200 kg / m3). Equipped with a bearing pressure compensation chamber.

300 000 ₽To order, production 2-4 weeks -

Mini-plant SSM-250-15M for the production...

A new type of foam generator is integrated into the design of the SSM-250-15M mini-plant, as well as a foam concentrate feed pump. Application of the mini-plant: for monolithic filling with foam concrete or the manufacture of foam blocks of various densities (from 150-1200 kg / m3). The productivity of the equipment is 1.5-2.0 m3 / hour (15 cubic meters,...

307 000 ₽В наличии -

Mini-plant SSM-250-15MK with compressor

A new type of foam generator CCM-PG-300 is integrated into the design of the SSM-250-15MP mini-plant, as well as a pump for feeding the foam concentrate. The standard equipment is complemented by a compressor. Application of the mini-plant: monolithic filling with foam concrete or production of foam blocks of various densities (from 150-1200 kg / m3).

319 000 ₽In Stock -

Mini-plant SSM-500-30M, equipment for foam...

Mini-plant CCM-500-30M is a renewal line built on the basis of a mixer with a working capacity of 510 liters. A new generation foam generator is integrated into its design, providing a homogeneous homogeneous mass and a pump for feeding the foam concentrate.

483 000 ₽In Stock -

Mini-plant SSM-500-30M1, automatic batching

The new version of the mini-plant SSM-500-30M1 is equipped with an electronic system for dosing water and foam. And also an SSM-FC-500 foam generator is installed in the platform of the mini-plant.

512 000 ₽Под заказ, производство 2-4 недели -

Mini-plant SSM-1000-40M, equipment for...

The updated design of the SSM-1000-40M mini-plant has a built-in foam generator and a pump for feeding the foam concentrate, as well as the bearing assembly of the mixer is equipped with a pressure compensation chamber to increase the service life of the entire assembly and eliminate the loss of cement laitance.

664 000 ₽Под заказ, производство 2-4 недели -

Mini-plant SSM-1000-40M1, automatic batching

Mini-plant CCM-1000-40M1, relative to its older version CCM-1000-40M, has been supplemented with electronic dosage of water and electronic dosage of foam. An integrated new generation foam generator and a mixer equipped with a durable and technically efficient bearing unit with a pressure compensation chamber remain unchanged in the design of the mini-plant.

687 000 ₽Под заказ, производство 2-4 недели -

Mini-plant SSM-1500-55M

The mini-plant was created on the basis of a mixer with a working capacity of 1550 liters. A new generation foam generator is built into the design of the CCM-1500-55M mini-plant, which guarantees the generation of a homogeneous foam mass with closed pores, and a pump for feeding the foam concentrate. The productivity of the plant is 5-7 m3 / hour.

780 000 ₽To order, production 2-4 weeks -

Mini-plant SSM-1500-55M1, automatic batching

Electronic water dosing and electronic foam dosing are built into the design of the modernized SSM-1500-55M1 mini-car, and the SSM-FC-500 foam generator is integrated. The productivity of the plant is 5-7 m3 / hour.

836 400 ₽On order, production 2 weeks -

Foam generator for foam concrete SSM-FC-500

Foam generator for the production of foam concrete SSM-FC-500 is one of the best on the market, has an adjustable frequency of foam formation, from 6 to 50. A wide range of foam density adjustment, from 20 to 200 grams per liter. Universal, works on all types of foamers, both domestic and foreign.

-

Metal block molds

Metal high-precision molds for 28 blocks of wall foam blocks with dimensions: 600 x 300 x 200 = 1 m³.

63 900 ₽ 71 000 ₽ -10%Reduced price!In Stock -

PVC plastic hose D50mm

Sleeve (hose) plastic PVC (B) d = 50x62mm P = 5atm made of transparent plastic (PolyVinylChloride), reinforced by synthetic (polyamide) thread. Operable at temperatures from -10C to +60C.

900 ₽In Stock -

Foam generator SSM-PG-500

Foam generator SSM-PG-500 - mobile unit of aerodynamic foam generator with a capillary barrel 900 mm is designed for generating foam for various purposes.

75 810 ₽ 79 800 ₽ -5%Reduced price!In Stock -

Mini-Factory SSM-E-200/250, Economy

Mini-plant SSM-E-200/250 Economy is a simplified version of the company's standard units of serial models SSM-200-12M or SSM-250-15M.

218 000 ₽In Stock -

Universal mini plant SSM-300, for foam...

Mini-mill SSM-300 is a versatile solution and is designed to address a wide range of tasks in the field of construction and production of finished products (blocks, foam blocks).

515 400 ₽In Stock -

SSM-50 mini-plant (laboratory station)

Model SSM-50-M1 mini plant has a small mixer of 50 liters, a high-performance foam generator and a reliable drive. It is designed for the production of foam concrete with capacity up to 0.5 m3/hour. It is often used for laboratory purposes: formulation selection, testing of raw materials and additives.

176 870 ₽In Stock -

SSM-500-30U mini plant for the production...

Mobile equipment for the production of foam concrete, polysterene concrete and other types of cellular concrete.

588 000 ₽In Stock -

Sieve (round sieve) for sand and other raw...

Drum-type sieve (round sieve) CCM-KS2 is designed for sifting sand and other raw materials. The rotation adjusts to your raw material with a speed control. Various modifications are available.

102 300 ₽In Stock -

Metal block molds

High-precision metal molds for 28 blocks of wall foam blocks with dimensions: 600 x 300 x 200 = 1 m³.

37 100 ₽In Stock -

Mini-plant SSM-500 UNIVERSAL, AUTOMAT for...

Mobile equipment for the production of concrete with a fraction of up to 25 mm, foam concrete, polystyrene concrete and other types of mortar.

638 400 ₽ 672 000 ₽ -5%Reduced price!In Stock -

Mini-plant CCM-250 Universal AUTOMATOR

A new type of foam generator CCM-PG-300 is integrated into the design of the SSM-250-15MP mini-plant, as well as a pump for feeding the foam concentrate. The standard equipment is complemented by a compressor. Application of the mini-plant: monolithic filling with foam concrete or production of foam blocks of various densities (from 150-1200 kg / m3).

411 990 ₽ 443 000 ₽ -7%Reduced price!Под заказ, производство 2-4 недели -

Complex SSM-OT-500 production of foam...

The complex is designed for the production of foam concrete and/or polysterene concrete with a capacity of at least 4 m3 per hour.

620 000 ₽In Stock -

-

-

-

Complex SSM-OT-200 production of foam...

The complex is designed for the production of foam concrete and/or polysterene concrete with a capacity of at least 1,5 m3 per hour.

458 000 ₽In Stock -

Complex SSM-OT-250 production of foam...

The complex is designed for the production of foam concrete and/or polysterene concrete with a capacity of at least 2,2 m3 per hour.

504 200 ₽In Stock -

Complex SSM-OT-1000 production of foam...

The complex is designed for the production of foam concrete and/or polysterene concrete with a capacity of at least 6 m3 per hour.

997 000 ₽In Stock -

Complex SSM-OT-300 production of foam...

The complex is designed for the production of foam concrete and/or polysterene concrete with a capacity of at least 3.5 m3 per hour.

568 000 ₽In Stock -

-

-

Equipment for the production of foam concrete

The mini-factories of SSM-Holding are reliable mobile equipment for the production of foam concrete. Absolutely all mini-factory models are used not only at the construction site for the production of monolithic foam concrete at the facility, but also in the workshop for the production of foam blocks and elements for the erection of houses and buildings (walls, floors, etc.), as well as for insulation of roofs, floors, attics .

Installations with a mixer volume of 200 to 500 liters are mounted on four wheels, two of which are swivel, which makes it easy to maneuver on the construction site or move around the workshop. Equipment with a mixer of 1000 liters or more is installed on four fixed wheels. Each unit is equipped with a foam generator for foam concrete with a pump for supplying foam concentrate. The case of the mini-factory is treated with Hammerite paintwork, which provides protection of the product from corrosion for 8 years.

Throughout the life of the equipment, CCM-Holding provides its customers with information and technological support.

Production of foam concrete

To start the equipment does not require any serious work skills. It is necessary to determine the installation location of the equipment, connect air and water to it, then, according to the instructions, configure the operation of the foam generator.

The equipment is intended for the manufacture of foam concrete with a density of 150-1200 kg / m3. The production of 1 m3 of foam concrete heat-insulating and structural, brand D600 (compressive strength 20 kg / cm2) requires:

- Cement M500 D0 310 kg;

- Sand with a fraction of up to 3 mm 220 kg;

- Foam 1.15 kg (deviation is possible, depending on the manufacturer of the foaming agent).

At the output, we have a foam block of the highest quality - in other words, a bio block that complies with the state standard in all respects: compressive strength, frost resistance, sorption moisture, vapor permeability, etc., which is not available using synthetic foam concentrates.

Compliance with the regulations for the preparation of foam concrete and the use of a set of mini-factories SSM-Holding guarantees quick access to GOST 25485-89, - the manufacture of non-autoclaved foam concrete according to technical parameters corresponding to the state standard of the Russian Federation.

The mixture is unloaded by supplying compressed air to the mixer from the compressor.

Equipment advantages

Long-life bearing assembly

The entire model range of foam concrete production plants is equipped with a bearing assembly with a pressure compensation chamber. This type of bearing assembly should be used in the mixers used overpressure. Only such bearings are used in professional construction equipment of domestic and foreign production, which use compressed air to unload the mixture. Such an assembly is superior to all types of bearing assemblies, including a remote bearing over a considerable distance.

Reliable drive

About 10 years ago, in mixers from 0.5 m3 and more, SSM-Holding (Severstroymaterialy Group of Companies) switched to a pulley-belt drive, using a cylindrical gearbox connected to the shaft, through a sleeve-finger coupling. The purpose of the transition was to bring the number of complaints to “0”. This is an expensive drive, where the gearbox has two protection levels:

- Belts;

- Coupling;

- Electronics.

An acceptable economy class drive is a pulley-belt - gear for small mixers up to 0.3 m3. We do not pursue low cost - we offer a quality product. Our production uses only reliable materials and technologies!

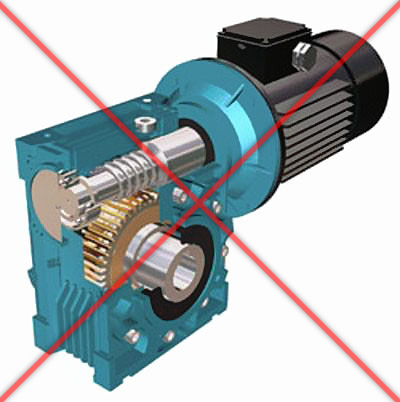

Why do not we use a gear motor, as other companies do?

The use of a gear motor would reduce the cost and, consequently, the final price of the equipment, but there are serious arguments that cannot be neglected in the manufacture of professional equipment for the production of foam concrete.

The fact is that worm gearboxes, motor gearboxes (see figure) have a relatively short service life as a result of rapid wear during friction in the joints. This is due to the fact that the interacting pair of "worm" - "gear" are made of various kinds of metal alloys. "Worm" made of solid steel, gear made of bronze alloy. In Russia, construction machines and mechanisms operate in medium-heavy operating conditions. Any load that differs from the uniform, even short-term load (getting large inclusions, lumps, short-term overload, etc. into the mixer) will certainly lead to the "gear" being eaten out by the hard-alloy "worm". Jamming of the shaft often leads to failure of the worm pair, i.e. the gearbox. In general, any worm gear drive is not intended for use in construction vehicles and machinery.

Foam generator provides maximum foam volume

Any protein foaming agent from both domestic and foreign manufacturers is suitable for the operation of the foam generator. The foam generator for the production of fourth-generation foam concrete, which are equipped with mini-plants, is equipped with an additional foaming unit that allows the production of ultra-light foam concrete D150-D300 on inexpensive protein foams. The pores of the foam are uniform, very small ~ 0.1-0.3 mm, closed structure.

Unloading foam concrete

Transportation of the finished mixture is carried out by compressed air from the compressor. This type of discharge does not require the use of a mortar pump.

Increased maintainability

All mini-factories are made taking into account the possibility of convenient control of the state of units and parts, their availability and ease of removal.